While the dream of a space elevator still lies on the technological horizon, some of the work to make it real is already underway — not in orbit, but much closer to home. Around the world, engineers are building and testing machines that climb tethers, cables, and vertical lines in challenging environments. These systems may look humble next to a 100,000-kilometer ribbon to space, but they provide real-world platforms for learning how climbers might one day ascend the sky.

While the dream of a space elevator still lies on the technological horizon, some of the work to make it real is already underway — not in orbit, but much closer to home. Around the world, engineers are building and testing machines that climb tethers, cables, and vertical lines in challenging environments. These systems may look humble next to a 100,000-kilometer ribbon to space, but they provide real-world platforms for learning how climbers might one day ascend the sky.

So, for this edition of the Weekend Walkabout, we’re hitting the road — and the rails, and the racks — to visit some of the real-world places where Earth-bound climbers are already being developed, tested, and deployed. Each stop gives us a glimpse into technologies that could one day help payloads and passengers rise steadily into space.

Rottweil, Germany — Elevator Test Towers That Reach for the Sky

Rottweil, Germany — Elevator Test Towers That Reach for the Sky

Our first stop is in Rottweil, where TK Elevator built a 246-meter testing tower — one of the tallest in Europe. Inside are shafts designed to trial ultra-lightweight elevator cars, regenerative braking systems, and vertical control tech under real-world wind and weather conditions. While it’s not climbing to geostationary orbit, it’s the kind of environment where future space elevator climber tech can be refined and proven.

Medellín, Colombia — Urban Ropeways in the Clouds

Medellín, Colombia — Urban Ropeways in the Clouds

Next, we head to Medellín, where the Metrocable system redefined how cities connect hard-to-reach communities. Designed to climb steep slopes with minimal land disruption, these cable cars are a case study in weatherproof, load-balanced tethered transit — including how to stabilize systems in high winds and heavy use. It’s the kind of design thinking that may be essential for early-stage climbers moving through Earth’s turbulent lower atmosphere.

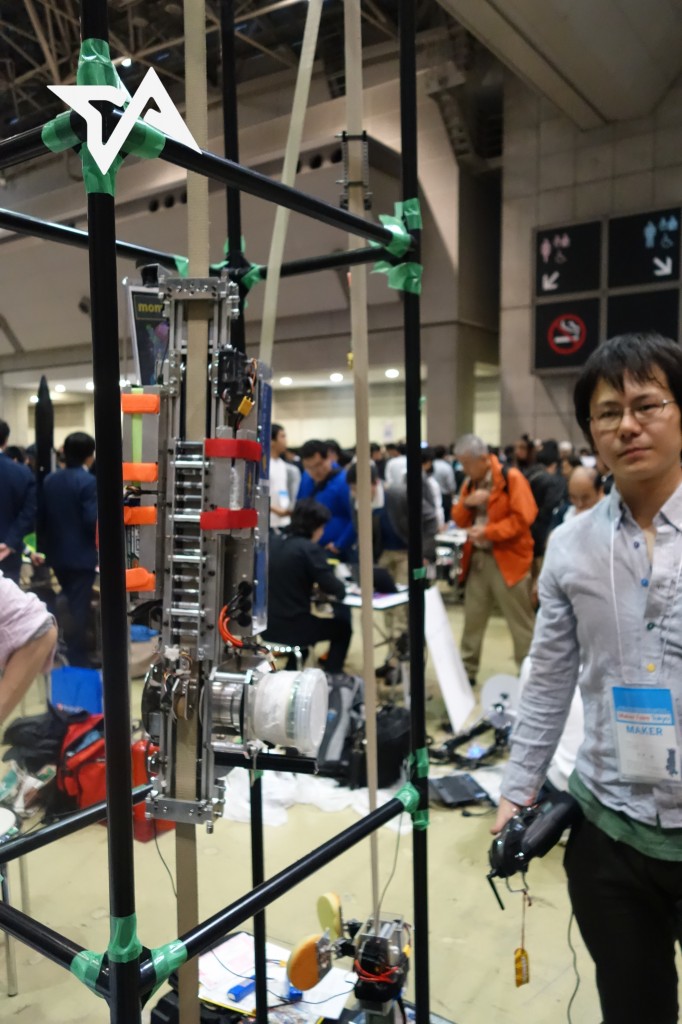

Tokyo, Japan — Warehouse Robots and Vertical Precision

In Tokyo and across Japan, automated storage and retrieval systems (AS/RS) quietly operate in high-density warehouses, where robotic lifters climb, sort, and retrieve items with astonishing accuracy. These systems solve many of the same problems that space elevator climbers will face — efficient power use, vertical coordination, and collision-free operation. Think of them as scaled-down, rapid-cycle testbeds for vertical movement.

Tignes, France — Ropeway Engineering in the Alps

Tignes, France — Ropeway Engineering in the Alps

In the French Alps, near Tignes, ski gondolas and cable cars ascend rugged peaks in extreme weather. The environment here demands careful planning around cable tension, vibration damping, and support structure integrity — all of which will be critical as we design kilometer-scale tethers that must survive the elements for decades.

Mojave Desert, USA — Laser-Powered Climbers Race Skyward

Mojave Desert, USA — Laser-Powered Climbers Race Skyward

Finally, we land in the Mojave, where NASA’s Power Beaming Challenges once showcased solar and laser-powered climbers racing up vertical tethers. These competitions pushed the limits of wireless power transfer, a likely requirement for actual space elevator climbers, which can’t afford to carry heavy batteries or fuel cells.

From Factory Floors to Orbit

Earth-bound systems can’t fully replicate the vacuum of space, microgravity, or the sheer length of a real tether. But they give us something just as valuable: hands-on testing platforms. We can prototype, stress, and refine climber technologies in ways that would be prohibitively expensive — or outright impossible — to do in orbit. Whether powered by solar, battery, or beam, these systems let us iterate. Fail fast. Improve faster.

So next time you ride an elevator, spot a cable car, or see a robot climbing a warehouse rack, take a moment to think about where that tech might eventually lead. Every climber that crawls up a cable today brings us a little closer to climbing the sky tomorrow.

Translation Project: Woven Pathways to the Sky

Translation Project: Woven Pathways to the Sky

Every week, we explore how the phrase “space elevator” might be expressed in a different language — a small reminder that the dream of space belongs to the whole world.

This week, we take inspiration not from future tech, but from a masterpiece of ancient engineering: the Inca rope bridges of the Andes.

Built entirely from hand-woven grass, these suspension bridges — the most famous of which is Q’eswachaka — spanned deep gorges and connected the vast Inca Empire. Renewed annually through community ritual, Q’eswachaka is often called “the last Incan rope bridge”, and it’s still in use today. The bridge’s design required precise tensioning, careful load balancing, and total trust in the materials — sound familiar?

So, for this week’s Translation Project, we turn to Quechua, the Indigenous language of the Andes, still spoken by millions in Peru, Bolivia, Ecuador, and beyond.

What might “space elevator” look like in Quechua?

Hanan pampa chuklla (A conceptual approximation: “skyward lifting platform”)

hanan = “above” or “sky”

pampa = “plain” or “platform”

chuklla = loosely adapted from pulley/elevator concepts

Like the bridge itself, this translation is woven from context and tradition, not just vocabulary. It reminds us that the spirit of the space elevator — a path to the heavens, built strand by strand — is something many cultures have imagined in their own way.

And that’s a wrap for this week!

Picture credits:

TK Tower – By Wladyslaw Sojka – Own work, FAL

Q’eswachaka – Rutahsa Adventures

Ropeway Engineering in the Alps – Société des téléphériques de Grande Motte (STGM)

Laser powered Climber – NASA

Just a quick note to let all my readers know that the June issue of the ISEC Newsletter has just been released.

Just a quick note to let all my readers know that the June issue of the ISEC Newsletter has just been released.

While the dream of a space elevator still lies on the technological horizon, some of the work to make it real is already underway — not in orbit, but much closer to home. Around the world, engineers are building and testing machines that climb tethers, cables, and vertical lines in challenging environments. These systems may look humble next to a 100,000-kilometer ribbon to space, but they provide real-world platforms for learning how climbers might one day ascend the sky.

While the dream of a space elevator still lies on the technological horizon, some of the work to make it real is already underway — not in orbit, but much closer to home. Around the world, engineers are building and testing machines that climb tethers, cables, and vertical lines in challenging environments. These systems may look humble next to a 100,000-kilometer ribbon to space, but they provide real-world platforms for learning how climbers might one day ascend the sky.

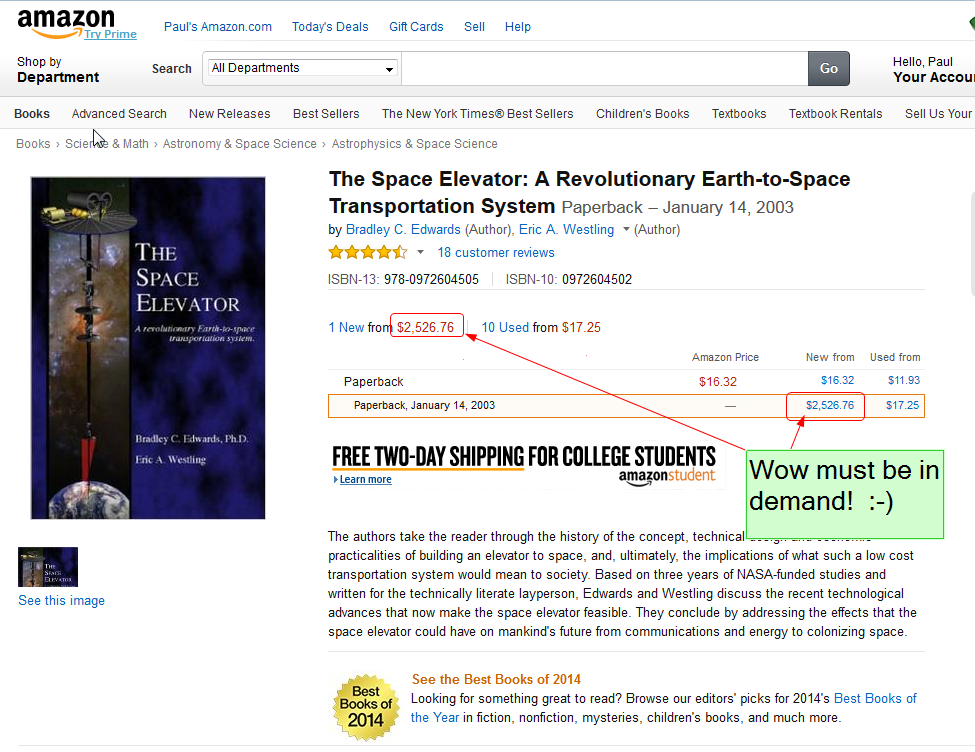

Just a quick update on some blog maintenance and cool finds for space elevator enthusiasts!

Just a quick update on some blog maintenance and cool finds for space elevator enthusiasts!

I’ve received a few emails (thank you!) from readers who note that I have a whole host of broken links in my sidebar.

I’ve received a few emails (thank you!) from readers who note that I have a whole host of broken links in my sidebar.

TwistedMojo has a new episode out in the

TwistedMojo has a new episode out in the

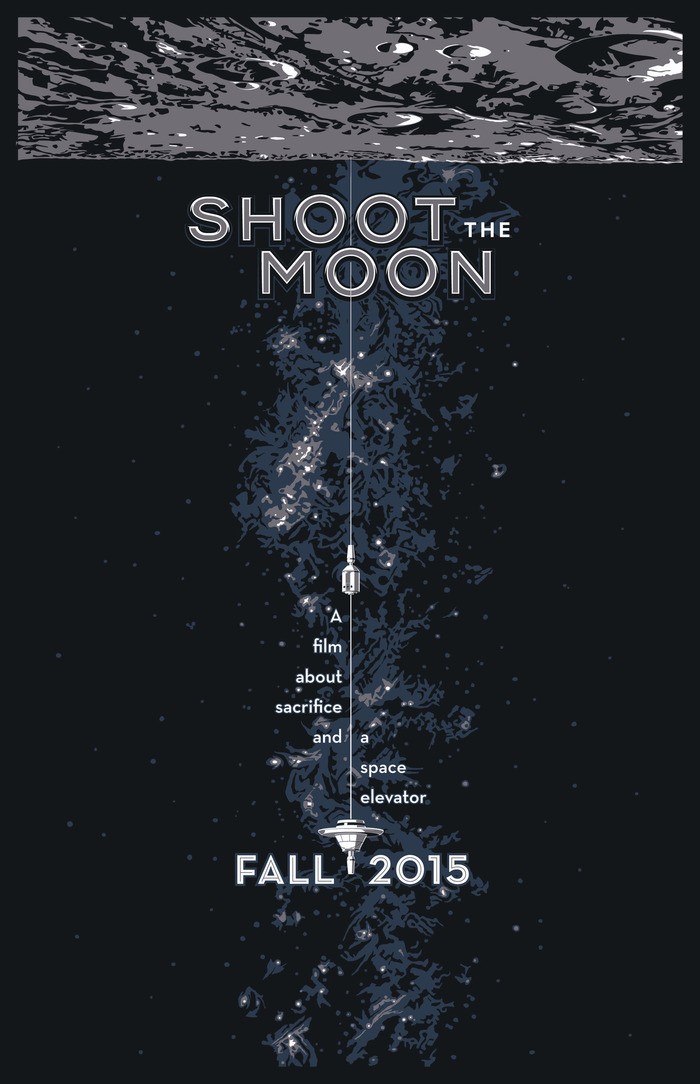

Making the rounds over the past several days has been the BBC Future article

Making the rounds over the past several days has been the BBC Future article  Just a reminder that this is the last week for the 2015 ISEC membership drive!

Just a reminder that this is the last week for the 2015 ISEC membership drive! n/seattle

n/seattle

The January, 2015 eNewsletter from the

The January, 2015 eNewsletter from the

It’s the holidays, family is in town and there are a few other things going on, so I’m taking a break from blogging.

It’s the holidays, family is in town and there are a few other things going on, so I’m taking a break from blogging. At the previous two

At the previous two

I’ve got not one, not two, but THREE projects in the works for this blog.

I’ve got not one, not two, but THREE projects in the works for this blog.

Does SETI need to shut up? Speaking of what’s “out there”, I’ve always been interested in the

Does SETI need to shut up? Speaking of what’s “out there”, I’ve always been interested in the

The ISEC

The ISEC  In this Weekend Walkabout, we keep it simple but definitely not local.

In this Weekend Walkabout, we keep it simple but definitely not local.

This is cool… Reader Chris Hibbert has pointed me to a

This is cool… Reader Chris Hibbert has pointed me to a  Each year, the

Each year, the